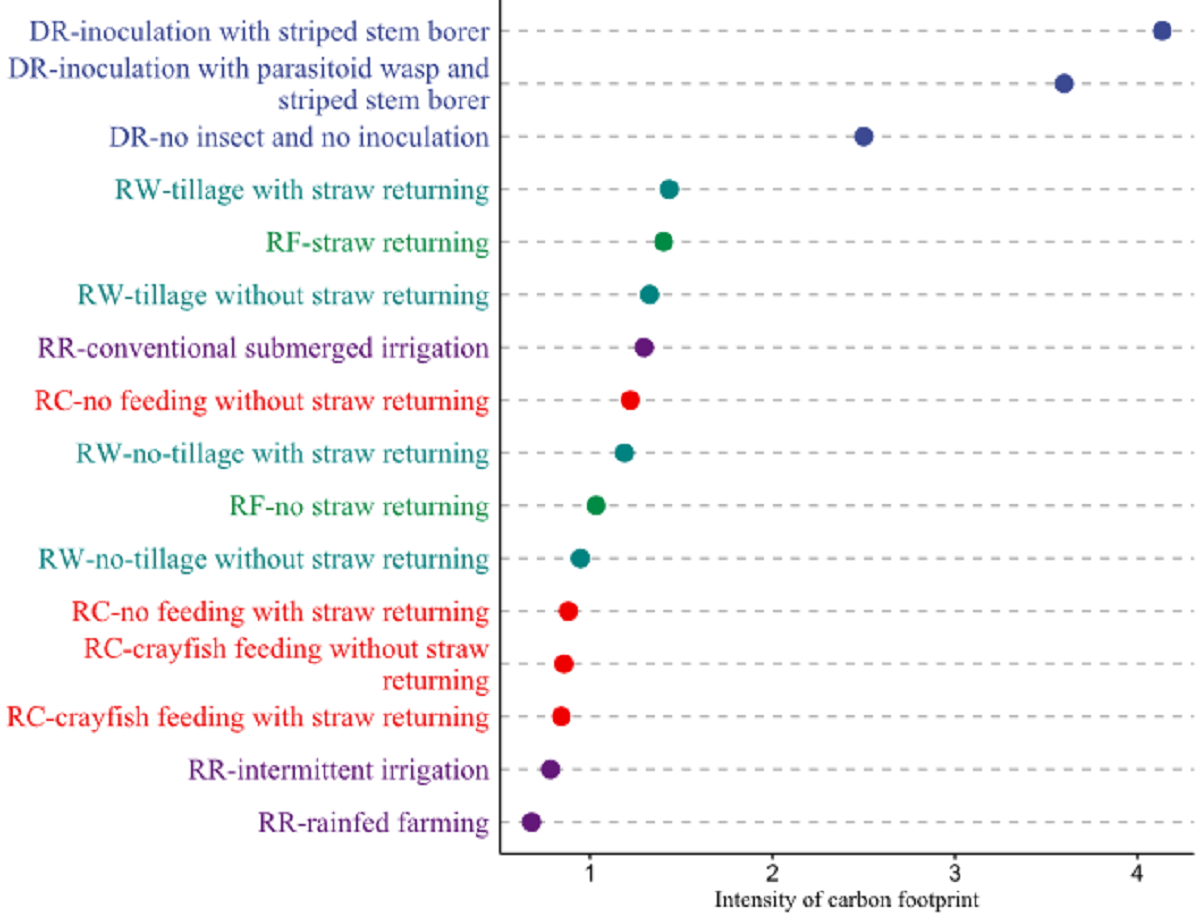

不同稻作系统的单位经济收益碳足迹 (kg CO2-eq yuan-1)

南湖新闻网讯(通讯员 阿依吐拉•买买提祖农)近日,我校宏观农业研究院、植物科学技术学院农业生态研究团队与中国农业科学院农业环境与可持续发展研究所合作研究,回答了不同水稻生产系统如何实现固碳减排的问题。

该研究基于农业生态团队在湖北省不同试验站采用统一的静态箱-气相色谱法测定的稻闲、稻油轮作、稻麦轮作、双季稻和稻虾共作等水稻生产系统的CH4和N2O排放试验数据,结合生物地球化学循环DNDC(DeNitrification DeComposition)模型进行模拟分析。在对每个系统进行模型校正、验证后,将观测结果统一尺度进行模拟比较,并分别采用基于过程的生命周期评估(PLCA)方法和成本效益分析方法对生产系统的碳足迹和经济效益计算,系统评估不同水稻生产系统不同减排措施下的经济产出和碳足迹。

研究结果表明,每种水稻生产系统需要配置不同的减排措施,才能够实现高收入-低排放,并且相同的措施在不同模式中的减排角色不同。此外,经过对系统不同组分碳排放结果的分析,得到减少氮肥用量、减少机械投入成本分别是稻旱轮作系统、双季稻系统最重要和有效的减排措施。该研究可为不同水稻生产系统增效低碳生产提供技术指导!

研究成果以“Comparing rice production systems in China: Economic output and carbon footprint”为题发表在Science of the Total Environment上,宏观农业研究院凌霖博士后为第一作者,曹凑贵教授为通讯作者。上述研究获得国家重点研发计划项目和中央高校基本科研业务费专项资金等项目的共同资助。

论文通讯作者(曹凑贵)团队经过10多年稻作系统固碳减排研究,提出了“增汇、降耗、减排、循环”的低碳稻作理论,出版了《低碳稻作理论与实践》专著。近期还发表了题为“水稻生产碳中和现状及低碳稻作技术策略”(http://hnxbl.cnjournals.net/hznydxzr/article/pdf/20210302)的综述论文。团队相关研究可为助力实现国家“双碳”目标提供重要支撑。

审核人:曹凑贵 游良志

【英文摘要】

In recent years, many rotational and integrated rice production systems coupled with several greenhouse gas (GHG) emissions mitigation practices have been developed and adopted for demand of low carbon production. However, there have been only few studies about comparisons on the balance between high production and mitigation of GHG emissions in different rice production systems. We therefore aimed to evaluate economic output and carbon footprint of different rice production systems, based on several long-term experiments conducted by our lab. CH4 andN2O emission were measured by the same static chamber/gas chromatogram measurement procedure in different rice production systems, including rice-fallow, rice-rapeseed, rice-wheat, double rice, and integrated rice-crayfish production system. Then, we applied the DeNitrification DeComposition model to simulate CH4 and N2O emission over different years under the same condition for comparison. Carbon footprint was calculated following the process-based life cycle assessment (PLCA) methodology. The economic benefit of rice production systems was assessed by cost-benefit analysis. According to the analysis, the double-rice production system exhibited the highest intensity of carbon footprint (ICF = 4.14 kg CO2-eq yuan−1), rain-fed treatment in the rice-rapeseed system had the lowest (ICF = 0.68 kg CO2-eq yuan−1). The intensity of carbon footprint in different treatments in the integrated rice-crayfish production system was around 0.8 kg CO2-eq yuan−1. Overall, the results of this case study suggest: (1) the proposed practices in different rice production systems are no straw returning (rice-fallow), no-tillage without straw returning (rice-wheat), rain-fed farming (rice-rapeseed), no insect and no inoculation (double rice), and feeding with straw returning (rice-crayfish); (2) rotational and integrated systems can achieve high net output with low carbon emission; (3) reducing the amount of nitrogenous fertilizer application is the most important and effective GHG mitigation practice for rotational systems.